This month, I will be teaching a few MIT Media Lab graduate students and doing a bit of a “geek tour” of Shenzhen – we will visit several factories and live among the electronic markets to facilitate new directions and expand horizons in the students’ hardware-oriented research projects.

As part of the course, they will learn how to scale up their research utilizing the China manufacturing ecosystem. These lessons may also be useful for Makers looking to bootstrap a product in moderate volumes (hundreds to thousands of units). I will share some tips and insights from the course in four posts over the next month covering:

- Getting a quotation: documentation standards (how to make a BOM)

- Process optimization: design for manufacturing and test jigs

- Industrial design for startups: guerrilla engineering on a shoestring budget

- How to pick a factory: building and maintaining partnerships

Part 1 of 4: The Quotation (or, How to Make a BOM)

Most Makers trying to scale up quickly realize the only practical path forward is to outsource production. If only outsourcing were as easy as schematic + cash = product! Whether working with the assembly shop down the street or going to China, a clear and complete bill of materials (BOM) is the first step to outsourcing production.

Every single assumption, down to the color of the soldermask, has to be spelled out unambiguously for a third party to faithfully reproduce a design. Missing or incomplete documentation is the lead cause of production delays, defects, and cost overruns. So, we will start the series on the topic of making a complete and accurate BOM for quotation.

Let’s consider a simple case study. Suppose we Kickstarted a bicycle safety light. It contains a circuit using the 555 timer to flash a small array of LEDs. After a great marketing campaign, we now have to fill several hundred orders in a few months’ time.

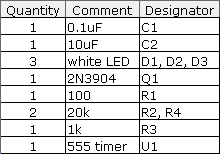

At this point, here’s how the starting BOM might look:

This BOM, along with a schematic, is likely sufficient for an engineer to reproduce the prototype, but this is far from adequate for a manufacturing cost quotation. Here’s some of the things missing from the BOM:

- Approved manufacturer for each component

- Tolerance, material composition, and voltage spec for passive components

- Package type information for all parts

- Extended part numbers specific to each manufacturer

Furthermore, the table above addresses only the electronics BOM. A complete BOM for an LED flasher also needs to include the PCB, battery, plastic case pieces, lens, screws, any labeling (for example, a serial number), a manual, and packaging (plastic bag plus cardboard box, for example). There may also need to be a master carton as a single boxed LED flasher is too small to ship on its own. Although cardboard boxes are cheap, they aren’t free, and if they aren’t ordered on time, inventory will sit on the dock until a master carton is delivered for final pack-out prior to shipment.

Here’s a little more about each of the missing items from the example BOM.

Approved manufacturers

A proper factory will require the allowed manufacture(s) to be specified for every part. This is frequently referred to as the “AVL”, or Approved Vendor List. A manufacturer is not a distributor (i.e., Digikey, Mouser, Avnet); a manufacturer is the actual company that makes the part. A capacitor, for example, could be made by TDK, Murata, Taiyo Yuden, AVX, Panasonic, Samsung, etc. You’ll be surprised how many times I’ve reviewed a BOM listing “Digikey” or some other distributor as the manufacturer for a part.

While it may seem silly to trifle over who makes a capacitor, there are definitely situations in which the maker of a component matters – even for the humble capacitor. For example, blindly substituting the filter capacitors on a switching regulator, even if the substitute has the same rated capacitance and voltage, can lead to unstable operation and even boards catching fire.

Of course, there are times when one is truly insensitive to the manufacturer, in which case I would mark on the BOM “any/open” for the AVL (particularly true for things like pull-up resistors). This invites the factory to suggest their preferred supplier on your behalf.

Tolerance, composition, and voltage spec

For passive components that are marked as “any/open”, there are some key parameters that should always be specified in a BOM to ensure the right part is purchased:

- For resistors, at a minimum the tolerance and wattage should be specified. A 1k, 1% 1/4W carbon resistor is very different beast from a 1k, 5% 1W wirewound resistor!

- For capacitors, at a minimum the tolerance, voltage rating, and dielectric type should be specified. For special applications, certain parameters such as ESR or ripple current tolerance also need to be specified. A 10uF, electrolytic, 10% 50V capacitor has vastly different performance at high frequencies compared to a 10uF, X7R [ceramic], 20% 16V capacitor.

- Inductors are sufficiently specialized that it’s not recommended to ever leave them as “any/open”. For power inductors, core composition, DCR, saturation, temperature rise current, are the basic parameters, but there is also no standard for casing like there is for resistors and capacitors. Furthermore, important parameters such as shielding and potting, which can have material impacts on the performance of a circuit, are often implicit in a part number; hence, it’s best to simply fully specify the inductor and not leave it any/open. The same goes for RF inductors.

Electronic component form factor

It’s always important to fully specify the form factor, or “package type”, of a component. Poorly specified or under-specified package parameters can lead to assembly errors. Beyond the basic parameters such as the EIA or JEDEC package code (0402, 0805, TSSOP, etc.), here are some other things to consider:

- For SMT packages, the height of a component can vary, particularly for packages larger than 1206, or inductors. Pay attention if the board is slotting into a tight case.

- For through-hole packages, lead pitch and component height should always be specified.

- For ICs, try to specify the common name that corresponds to the package, not just the manufacturer’s internal code (for example, a TI “DW” type package code corresponds to SOIC). It’s a good consistency check that can guard against errors.

Extended part numbers

Designers often think using abbreviated part numbers. A great example of this is the 7404. The venerable 7404 is a hex inverter, and has been in service for decades. Because of its ubiquity, the term “7404” can be used as a generic term for an inverter. However, when going to production, things like the package type, manufacturer and logic family must be specified. A complete part number might be 74VHCT04AMTC, which specifies an inverter made by Fairchild Semiconductor, from the “VHCT” series, in a TSSOP package, shipped in tubes. The extra characters are very important, because small variations can lead to big problems, such as quoting and ordering the wrong packaged device (and subsequently being stuck with a reel of unusable parts), or subtle reliability problems. In fact, I encountered a problem once due to a mistaken substitution of a “VHC” for the “VHCT” logic family part. This switched the input thresholds of the inverter from TTL to CMOS logic-compatible, and resulted in some units having an asymmetric response to input signals. Fortunately, I caught this problem before production ramped, avoiding a whole lot of potential rework or worse yet, returns.

Here’s another example of how missing a couple of characters can cost thousands of dollars. A fully specified part number for the LM3670 switching regulator might be LM3670MFX-3.3/NOPB. Significantly, if the /NOPB is omitted, the part number is still valid and orderable – but for a version that uses leaded solder. This could be disastrous for products exporting to a region, such as the EU, that requires RoHS compliance (meaning lead-free, among other things). A more subtle issue is the “X” in the part number. Part numbers with an “X” come with 3,000 pieces to a reel, and ones lacking an “X” come in 1,000 pieces to a reel. While many factories will question the /NOPB omission (since factories typically assemble RoHS documentation as they purchase parts), they will rarely flag the reel quantity as an issue. However, you care about the reel quantity because if you only wanted 1,000 pieces, including the X in the part number means you’ll be paying for 2,000 extra pieces you don’t need. Or, if you’re doing a much larger production run and you omit the X, you could be paying a premium for shipping three times the volume of reels for the same purchase quantity. Either way, the factory will quote the part exactly as specified, and you could be missing out on a cost savings if you’re not paying attention to the reel quantities.

The bottom line is that every digit and character counts, and lack of attention to detail can cost real money!

BOM Revisited

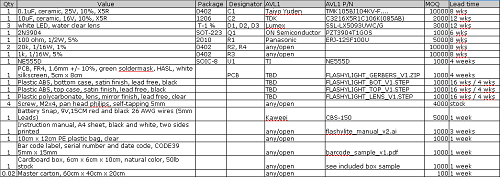

Here’s an example of how a proper, fully-specified BOM for quotation of the same project example above would look.

(click for a larger version, or get the original in open office format here)

Note that the BOM above doesn’t call out factory margin, labor for assembly, pack-out, shipping, duties, etc. These “soft costs” will be discussed in the final post of the series. However, it’s important to note that when building a business model, parts cost is not the only cost to consider — the above BOM just gets you started with the initial quotation process.

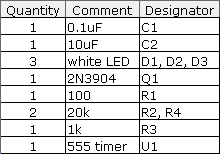

Let’s compare this to our original BOM for contrast:

There is big difference between a BOM that any engineer could take to produce a prototype, and a BOM that any factory could take to mass-produce a product.

Note that two additional columns have crept into the final BOM, the “MOQ” (minimum order quantity) and the “lead time”. These columns are irrelevant when building low-volume prototypes, as one would typically buy parts from distributors which have few MOQ restrictions and maintain stock on hand for next-day deliveries. However, when scaling into production, a big cost savings are realized by cutting the distributor overhead and buying through wholesale channels. In wholesale channels, MOQs and lead times matter.

The good news is the factory will fill in the MOQ and lead time as part of the quotation process. However, these are parameters that are helpful to be tracked from the beginning of a design. If the MOQ of a particular component is very high, one may have to buy massive numbers of excess parts which increases the effective price of the project. If the lead time of a part is very long, one may want to consider redesigning for a part with a shorter lead time. Using parts with shorter lead times not only saves time, it improves cash flow, as the last thing anyone wants to do is tie up cash on long-lead components 4 months in advance of any sales revenue.

Also note the inclusion of all the “miscellaneous” bits for the design inside the BOM, left out on the engineering prototype’s BOM. The miscellaneous bits are easy to forget, but a missing user manual in an initial BOM is often times not discovered until opening the final sample for approval, leading to a last-minute scramble to get it into the final product. Many, many products have been delayed or late simply because a user manual or box art was not completed and approved in time, and it sucks to have a hundred thousand dollars worth of inventory idling in a warehouse for want of a slip of paper.

Finally, it’s best practice to provide the factory with “golden samples” along with CAD files. These prototypes enable the factory to make smarter decisions about any ambiguities in the submitted BOM. It may suck to hand-solder together one more unit just for the factory, but in my opinion a few hours of soldering beats a week of trading clarifying emails with the factory.

Coping with Change

Designs change. Even if a design is perfect, sometimes vendors End-of-Life (EOL) components, forcing a change to the design. And let’s face it, not all design assumptions survive contact with real consumers. While the quotation process is fluid, it’s important to formalize the change process once crossing the threshold into production. It is best practice to use a written, formal Engineering Change Orders (ECO) to update the factory on any changes after the initial quotation is completed. An ECO template should have at a minimum the documentation detailing each part changed and brief explanation of why, along with a unique revision number for conveniently referencing the change down the road, and a method to record the factory’s receipt of the ECO paperwork. Failing to be thorough about ECOs and relying on casual emails will often lead to buyers buying the wrong part, or worse yet the factory installing the wrong part and entire lots being scrapped or reworked. Even after troubleshooting a problem with the factory engineers, I will still write up a formal ECO and submit it to the production staff to formalize the findings. I hate paperwork as much as the next engineer, but in production one small mistake can cost tens of thousands of dollars, and that thought keeps me disciplined on ECOs.

Stay tuned for next week when I cover design for manufacturing and test jigs.

[…] Att beställa och producera komponenter på rätt sätt (inkl från Kina) [www.bunniestudios.com] poäng | Postat januari 5 av Karsten Deppert […]

I saw on Akiba’s blog that you were going to held a 4 week workshop for MIT students regarding manufacturing in Asia and I felt I would trade a kidney to be able to attend it. I’m really glad you decided to write about it and I’m hopping you will complement with as many (gory) details as possible, maybe photos or movies. Is really great stuff and I don’t think there are many resources referencing it – in fact maybe you should consider writing another book ?

Excellent article, I’m starting to translate it in french.

All of this wisdom would have saved me hours of headache if I had known them before !

Thanks!

Translation complete! Next time it will be faster!

http://www.openmakersdaily.org/bunnie-huang-a-lusine-partie-1-sur-4-le-devis-ou-comment-faire-une-nomenclature/

Also, would you mind to share details about FCC and CE certification processes and what are your advices about that? I know they are not so important for the chinese market, but they are for all other parts of the world!

This step is frequently out of Maker’s minds because it’s not required for personal/hobby builds/kits.

Thank you, Bunnie.

I have read/heard several stories where trusting the manufacturer to “do the right thing” went very wrong. In other cases, the manufacturer pointed out problems and solutions to the designers and worked with them to make a good product.

Would you mind talking a little bit about how to identify “good” manufacturers for beginners in one of the following posts?

I think that’s the topic of the fourth part! Very interesting topic, indeed.

As a general advice I would suggest to trust the Murphy law and assume that every thing that can go wrong, will go wrong, and no to rely too much on manufacturer’s wisdom, even if he’s willing to help :)

Depends on the factory, and on the advice being sought/offered. For example, a factory might offer a design suggestion that could ease the handling of a circuit board during installation, which could save money during assembly.

One such example might be a request to keep the edges parallel so they can be aligned cheaply during testing and assembly, but including a break-away section so the finished board provides some needed clearance inside the package.

I haven’t tried it yet, but Aligni offers online BOM management tools that look interesting, free for open source hardware designs:

http://www.aligni.com/open/

the aligni link here is incorrect, it should be http://www.aligni.com/open-aligni/

Good stuff, Bunnie!

Excellent discussion of how to correctly specify parts to ensure that you get exactly what you need, not what you wanted. :)

As an old hand in the electronics field I can tell you that getting the wrong part in small quantities is just an annoyance, but having it happen in a production environment results in a bloody huge disaster 99% of the time. Ask me how I know.

Awesome post. Right in the middle of figuring this stuff out, so it’s very timely. I’m wondering if having the PCBA factory order the BOM is the way to go for first runs, or whether it’s safer to order the parts yourself and ship it to them (so you know that every part works)? Is it much cheaper to go with a Turnkey solution?

Very good, and applicable even if you aren’t going to China. For us, with a fairly low volume but a complex and expensive product, it’s been invaluable to work with experienced domestic contract manufacturers. The few dollars more per board it costs are more than made up in responsiveness, quick turnaround, and a fair bit of hand holding and guidance. Of course, that might be different if we were dealing with high volumes. The many issues that come up before and during production have been far easier to deal with, and can be addressed before production volumes need to be trashed or reworked.

The last paragraph could be a book. Factory record keeping is crucial to track issues when things stop working correctly. Parts change, sometimes even when the manufacturer doesn’t change the part number. We have seen issues when the manufacturing location was altered, even though it was the “same” part. And all changes are not necessarily fully documented. We experienced this with a stacked memory chip that could have cost us an entire production run if it hadn’t been fixable with a firmware change.

Wait…people will just TELL you this stuff? I had to learn everything the hard way. Every single point above, drilled in through one or more mistakes. :)

I spent the last 2 and 1/2 years working for a small company. We did our original production with a domestic contract manufacturer(CM). This company was local (nearby) to our design labs. The CM worked WITH US to make the production run successful. Our management then decided to move production to an Asian CM. It has been a Disaster. Bunny has nailed all the issues in his first article.

Great stuff Bunnie. I have been doing ERP systems for factories, run a factory, in greater China for a long time and these are the sort of things everyone needs to know. You really should write a book about this for product people and engineers. You experience has universally applicable guidelines tp follow that will work in SHenzhen or Sao Paolo and also China specific help. Keep it coming !

Unless you want your china mfg knocking you off or his employes provide as little as you can. Bring your own parts to the contract mfg and uv MARK THEM. Check that YOUR parts are used.

I’m not attempting to change the topic, just lookin for a little bit of insight because we are in the process of relocating and are in search of an legitimate moving company. We were thinking of using this company, Movers4Less 1992 N Main St Walnut Creek, CA 94596 – 925-309-6130. Is there some kind of movers fraud or review resource I can use to do a background check?

One good clue is that a company that dumps irrelevant spam into blog comments is probably not legitimate.

Although, of course, it would be easy enough for a company to go posting irrelevant spam naming one of its rivals, so I suppose we shouldn’t jump to conclusions.

this is a spam. This comment is abusing the page rank of this site to introduce an address. Spambots are more and more “intelligent” these days.

Since your in the Bay this is who I have used a number of times for small office moves http://commandermoving.com/

Couldn’t help but notice the screws in the “proper” BOM are not fully defined as there is no material specification listed. Also it should technically be M2x0.4 instead of M2x4

A couple of things –

I found it always helpful to put a revision level on the BOM itself, even if it’s just a date. I usually use the board revision and a number for the BOM revision. A1, A2, etc

Saving the BOM in structured text rather than a spreadsheet lets you easily use source code control to look at revisions and diffs.

Labels always seem to be a problem, even unchanging ones. It’s best to do a very specific assembly drawing for the labels, and if you want a serial number on each, be prepared to spend some time getting it right.

‘Indented’ BOMs are very helpful as the product gets more complicated – essentially the BOM is structured as a tree. This lets you do things like bring in a new board revision without massive changes to the upper level BOM.

You should all become educated in configuration management. Recommend CMII (not CMMI, which is aimed more at software).

For those with resources to invest, there are also many useful PDM (product data management) software packages out there e.g.Agile (Oracle), ematrix, etc. probably less expensive options too.

[…] The Factory Floor, Part 1 of 4: The Quotation (or, How to Make a BOM) […]

I’m surprised that you would specify the *schematic* and BOM. Who is layouting the PCB? I was expecting that you make the layout of the PCB and also hand them gerber files. Only then you can find out if the manufacturer is able to/confident to actually produce the board you want to build!

Is it possible to get things like really tiny pitch, flex layers, burried vias? I remember some trouble with local manufacturers who claimed they could do this but the first production run failed – many weeks were lost. One way to solve this is by using standard technology only.

For me it seems to be a simple manner to express the idea that a schematic + component values is sufficient to describe how a circuit works.

From an engineer perspective, the idea is that you can omit lots of details and the engineer will work them out got get something that works.

But the manufacturer is not expected to have anything to interpret, because any area of interpretation leaves room for differences with your original intended design.

Or, in other words, when you don’t describe your product properly, you can as well avoid giving the gerbers to the manufacturer ;)

Sorry, please don’t take the case study too literally. You’re right, you should also have the layout of the PCB specified, and if you look closely at the “final” BOM one of the files I recommend having is the gerbers for the PCB, as well as the 3D design files for the case (which are as important to a product quotation as the gerbers are). I didn’t include a layout in the case study because the specific layout itself isn’t relevant to the BOM documentation.

Microvia etc technology is possible in China but you have to carefully vet the factory and the manufacturer. After all, they design, prototype and make gobs of mobile phones in China and they all use microvia, flex layers, and buried vias — but it’s not something that every shop can do!

second paragraph: yes, one should really check with the manufacturer that the pcb design features are available in this fab. Once again “it depends” but it’s a general rule.

I have a story about that. For our product, the PCB design was very close to the design rules limits. The manufacturer was sub-contracting the PCBs. The PCB contractor made the prototype PCB without a problem, but later refused to produce the required large amount of production PCBs, because of design rules ‘violations’ that he did not talk about before!

And of course he did not tell that to us right after the prototype was made, but just before the production was supposed to start!

Wait… isn’t a prototype representative of production processes? you bet!

And voila, one more month of delays, and the next project won’t go to this contractor!

[…] Link […]

[…] The Factory Floor, Part 1 of 4:The Quotation (or, How to Make a BOM). Bunnie writes – This month, I will be teaching a few MIT Media Lab graduate students and doing a bit of a “geek tour” of Shenzhen – we will visit several factories and live among the electronic markets to facilitate new directions and expand horizons in the students’ hardware-oriented research projects. […]

Where substitution is permitted, presumably you need to track which vendor was used for various batches/serial numbers?

Something I’m fascinated about the process (I’m not in the industry) is the acceptance criteria; what do you do if you have a container of faulty product?

Great article!

Are there companies who will (for a fee) do all the dirty work above for you and possibly even tender out the work to a suitable factory?

Dragon Innovation is one such company. They are also involved in the HAXLR8R project.

http://www.dragoninnovation.com/overview/

Scott Miller, who co-founded Dragon Innovation, was on episode #113 of The Amp Hour podcast. It was a good show.

http://theamphour.com/the-amp-hour-113-sudden-sinoamerican-synthesis/

I would like to suggest that, if you have more than one BOM to maintain, invest in a piece of BOM software. I have used Parts&Vendors ( http://www.TriogyDesign.com ) for many years. I started out trying to use a spreadsheet but it just became too cumbersome when we needed to use the same part in several assemblies and to assign several manufacturer’s to a part. The software is available for $99 / seat and the license can be set up floating. I am not affiliated in any way with this company or their software other than the fact that I personally own a seat.

Hi Bunny, great article. I don’t know if you remember me, but I am Pete Dilworth (the dinosaur robot guy from the AI lab all those years ago), and I am going to be in Shenzhen this wednesday and thursday, also in HK this week, if you are around and have a free lunch to spare would love to chat, I am trying to do what you are teaching here.

[…] Bunnie blog, Jan […]

[…] great series of Bunnie Huang (who runs a great blog, by the way). This is the start of a four part series on outsourcing manufacturing. More specifically, to outsource to China, but many rules apply […]

[…] qui suit est donc la traduction de l’article de Bunnie Huang: The Factory Floor, Part 1 of 4: The Quotation (or, How to Make a BOM). C’est donc lui qui s’exprime à travers le « je » utilisé dans […]

[…] Improves the Bottom Line Let’s return to our LED blinker case study from part 1 of the series. Let’s say the prototype design calls for an array of three LEDs in parallel, each with its […]

[…] Huang posted an extensive explanation of how you’re doing your Bill Of Materials (BOM) all wrong. Here’s a taste. For the whole 5-course meal head over to his blog. Most Makers trying to […]

[…] posts in his The Factory Floor series on out-sourcing production to China. Read the first two parts here and here. The final two parts, Industrial Design for Startups and Picking (and Maintaining) a […]

[…] The Quotation (or, How to Make a BOM) On Design for Manufacturing Industrial Design for Startups Picking (and Maintaining) a Partner […]

[…] Getting a quotation: Documentation standards (how to make a BOM). […]

[…] On the Factory Floor Part 1 – The Quotation (or, How to Make a BOM) On the Factory Floor Part 2 – On Design for Manufacturing On the Factory Floor Part 3 – Industrial Design for Startups On the Factory Floor Part 4 – Picking (and Maintaining) a Partner […]

[…] On the Factory Floor Part 1 – The Quotation (or, How to Make a BOM) On the Factory Floor Part 2 – On Design for Manufacturing On the Factory Floor Part 3 – Industrial Design for Startups On the Factory Floor Part 4 – Picking (and Maintaining) a Partner […]

[…] On the Factory Floor Part 1 – The Quotation (or, How to Make a BOM) On the Factory Floor Part 2 – On Design for Manufacturing On the Factory Floor Part 3 – Industrial Design for Startups On the Factory Floor Part 4 – Picking (and Maintaining) a Partner […]

Manufacturing in China, even though it’s potrayed negatively in the media should definitley be on every serious businessmans mind.

3D TVs Falls into 2 different categories. 3D movies you view with active shutter glasses and 3D TV you view with polarized glasses.

The BOM could reference a specific version of a schematic as different versions may use different values. Don’t forget solder a/r, pcb issue, and whatever else is needed to do the job. Some component values may be SOT (set on test). Check the BOM carefully. I rushed a BOM job once and missed out a line or two. The job had to be hand finished which took a long time. It may be possible to consolidate the BOM if some values are similar. A part may be unavailable near the time of manufacturing so you should be ready to find alternatives. It may be something simple like a ROHS version or more complex like a chip gone obsolete.

Consider tempco’s, particularly capacitors. Y5V may be unsuitable.

Some manufacturers may have specific types of pad sizes and other requirements depending on the process used. For example it may be important to consider surface tension in solder, this can pull components off their pads (tombstoning).

Anyone who lives in Russia or knows a lot about Russia?

I’m stunned, I must say!