Recently, Akiba took me to visit his friend’s zipper factory. I love visiting factories: no matter how simple the product, I learn something new.

This factory is a highly-automated, vertically-integrated manufacturer. To give you an idea of what that means, they take this:

Ingots of 93% zinc, 7% aluminum alloy; approx 1 ton shown

and this:

Compressed sawdust pellets, used to fuel the ingot smelter

and this:

Rice, used to feed the workers

And turn it into this:

Finished puller+slider assemblies

In between the input material and the output product is a fully automated die casting line, a set of tumblers and vibrating pots to release and polish the zippers, and a set of machines to de-burr and join the puller to the slider. I think I counted less than a dozen employees in the facility, and I’m guessing their capacity well exceeds a million zippers a month.

I find vibrapots mesmerizing. I actually don’t know if that’s what they are called — I just call them that (I figure within minutes of this going up, a comment will appear informing me of their proper name). The video below shows these miracles at work. It looks as if the sliders and pullers are lining themselves up in the right orientation by magic, falling into a rail, and being pressed together into that familiar zipper form, in a single fully automated machine.

If you put your hand in the pot, you’ll find there’s no stirrer to cause the motion that you see; you’ll just feel a strong vibration. If you relax your hand, you’ll find it starting to move along with all the other items in the pot. The entire pot is vibrating in a biased fashion, such that the items inside tend to move in a circular motion. This pushes them onto a set of rails which are shaped to take advantage of asymmetries in the object to allow only the objects that happen to jump on the rail in the correct orientation through to the next stage.

Despite the high level of automation in this factory, many of the workers I saw were performing this one operation:

This begs the question of why is it that some zippers have fully automated assembly procesess, whereas others are semi-automatic?

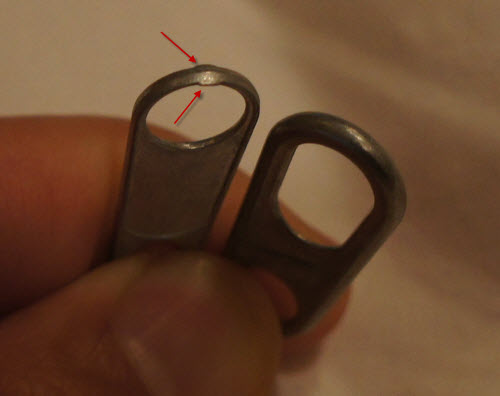

The answer, it turns out, is very subtle, and it boils down to this:

I’ve added red arrows to highlight the key difference between the zippers. This tiny tab, barely visible, is the difference between full automation and a human having to join millions of sliders and pullers together. To understand why, let’s review one critical step in the vibrapot operation.

We paused the vibrapot responsible for sorting the pullers into the correct orientation for the fully automatic process, so I could take a photo of the key step:

As you can see, when the pullers come around the rail, their orientation is random: some are facing right, some facing left. But the joining operation must only insert the slider into the smaller of the two holes. The tiny tab, highlighted above, allows gravity to cause all the pullers to hang in the same direction as they fall into a rail toward the left.

The semi-automated zipper design doesn’t have this tab; as a result, the design is too symmetric for a vibrapot to align the puller. I asked the factory owner if adding the tiny tab would save this labor, and he said absolutely.

At this point, it seems blindingly obvious to me that all zippers should have this tiny tab, but the zipper’s designer wouldn’t have it. Even though the tab is very small, a user can feel the subtle bumps, and it’s perceived as a defect in the design. As a result, the designer insists upon a perfectly smooth tab which accordingly has no feature to easily and reliably allow for automatic orientation.

I’d like to imagine that most people, after watching a person join pullers to sliders for a couple minutes, will be quite alright to suffer the tiny bump on the tip of their zipper to save another human the fate of having to manually align pullers into sliders for 8 hours a day. I suppose alternately, an engineer could spend countless hours trying to design a more complex method for aligning the pullers and sliders, but (a) the zipper’s customer probably wouldn’t pay for that effort and (b) it’s probably net cheaper to pay unskilled labor to manually perform the sorting. They’ve already automated everything else in this factory, so I figure they’ve thought long and hard about this problem, too. My guess is that robots are expensive to build and maintain; people are self-replicating and largely self-maintaining. Remember that third input to the factory, “rice”? Any robot’s spare parts have to be cheaper than rice to earn a place on this factory’s floor.

However, in reality, it’s by far too much effort to explain this to end customers; and in fact quite the opposite happens in the market. Because of the extra labor involved in putting these together, the zippers cost more; therefore they tend to end up in high-end products. This further enforces the notion that really smooth zippers with no tiny tab on them must be the result of quality control and attention to detail.

My world is full of small frustrations similar to this. For example, most customers perceive plastics with a mirror-finish to be of a higher quality than those with a satin finish. While functionally there is no difference in the plastic’s structural performance, it takes a lot more effort to make something with a mirror-finish. The injection molding tools must be painstakingly and meticulously polished, and at every step in the factory, workers must wear white gloves; mountains of plastic are scrapped for hairline defects, and extra films of plastic are placed over mirror surfaces to protect them during shipping.

For all that effort, for all that waste, what’s the first thing a user does? Put their dirty fingerprints all over the mirror finish. Within a minute of coming out of the box, all that effort is undone. Or worse yet, they leave the protective film on, resulting in a net worse cosmetic effect than a satin finish. Contrast this to a satin finish. Satin finishes don’t require protective films, are easier to handle, last longer, and have much better yields. In the user’s hands, they hide small scratches, fingerprints, and bits of dust. Arguably, the satin finish offers a better long-term customer experience than the mirror finish.

But that mirror finish sure does look pretty in photographs and showroom displays!

So you want the narrow end in first, or the tab will fall off the line. You need a step where you can push one tab at a time under a carefully shaped and spring loaded part. If the wide end is first, it should hit a sideways slope that will push it out. If the small end is first, it should move under this slope without hitting it, then hit a slope facing the other direction to hold it in place, pushing the spring upwards. Raising the first slope before the wide end of the tab can reach it.

Or something like that.

Jeremy,

If it were that simple, it’d already be on the machine. =)

I was thinking that modifying the mould to make the tab removable then having some step remove it and clean up the space where it was would be an easier solution.

Julian,

Just because something is obvious and simple doesn’t mean anyone else has ever thought of it before. Jeremy may well be right.

couldn’t you just make the zipper slightly wider at the top than at the bottom, essentially making one huge smooth bump?

My thought exactly.

Same effect, not perceived as a defect.

Slightly more expensive, of course, because it uses more metal.

An automated step to machine off the tab after the gravity alignment would do the trick.

That would … probably double the cost of the zipper, though.

And that adds up when you’re making them by the million.

Ah, but it probably cancels out when you’re also SELLING them by the million! If it costs 0.1 cent more to make them that way, then charge 0.1 cent more for the final clothing item that contains the zipper. DONE.

Put the tabs on the small hole and flip how it heads to the press.

The hand in the first video says that you were on the 31c3 : D

I SAW THAT TOO!!! I still have my mine on! http://666kb.com/i/d4uohz3r0byrthqyy.jpg

I wonder if the author of the blog will be on this years congress? (I will be there :-) Maye he can post a comment …

Application of tiny blob of something like wax, as way of giving the temporary weighting, hmm..

Interesting write-up. Thanks

Second thought. Problems in and of themselves are so inviting to solve, but I find myself shifting to how to solve how this person might not in fact lose their job, but rather have a piece of fish, or some veggies to go with their rice, and also wondering what the shifts and mind life is like for such an individual. Maybe you asked some of those people Bunnie?

> Application of tiny blob of something like wax, as way of giving the temporary weighting, hmm..

This just shifts the problem: the wax should only go on the small end, so you still need another mechanism to orient the zippers prior to applying the wax ;)

Exploiting the wedge shape seems like a better approach, but it’s not cheaper than rice.

Bowl feeder. Sorry I’m late…

I can think of at least 2 ways to sort the tabs orientation based on gravity or friction… but if it’s not cheaper than rice….

It would require only a VERY simple vision processing system tied to a solenoid to push the misaligned zippers off so that they could go back into the bin. On average half would come out right, so it’s just a matter of time before you got them all. This would be less than $1000 worth of computer and vision equipment. The software could be created using OpenCV and ODesk. You wouldn’t even need to be an expert. Easy peasy.

Add to that a few days of a decent programmer and we’re at $5000 just for developing the thing. At $1.50 per hour, this buys you two years of unskilled labor in China.

That ROI doesn’t look so good.

I am a decent programmer doing computer vision for a living but unfortunately (for me) I have to say that there are lots of on-the-shelf components that will make it possible to automate this task with no programmer in the loop.

They still are costly though but I think you can get this done for less than $1000.

That would be the case if each zipper factory had to produce its own solution to this problem.

Instead, this seems to be a good realm for some plucky Silicon Valley startup to build the thing and spread the programmer costs over dozens of installations.

There are companies like Keyence that make self-contained machine vision packages that can be set up in the field by non-programmers through a built in GUI in a very short period. It would take longer to install it than have it set up to reject parts in the wrong position.

I have been mesmerized by such feeders since I first saw them at a factory for drip irrigation emitters some 30 years ago. There was a lot of creativity in the design of the barriers for pushing the incorrectly oriented parts back into the bowl. I remember many of them made use of strategically placed compressed air nozzles.

I think a bifurcation in the path of the pullers and one or two compressed air nozzles should do the trick. Air flow can reliably distinguish ring-first pullers and apply torque to nudge them right or left.

I think you are on to something. An optical sensor trips for the zipper presence, a pin or burst of air will rotate or flip the zipper. Minimal hardware, thus minimal cost and maintenance.

[…] A Tale of Two Zippers « bunnie’s blog. […]

[…] http://www.bunniestudios.com/blog/?p=4364 […]

I do agree with you on polished plastic finishes!. So many products don’t need them, the waste. Some will make it to re-grind, most is thrown on the rubbish heap.

[…] joseph conrad is fully awesome “a highly-automated, vertically-integrated manufacturer” Visit a zipper factory and see how a perceived design flaw translates into a more labor-intensive […]

As an Actual Consumer, I don’t like the glossy finishes for exactly those reason, and to me they look and feel -cheaper- even though they cost more to make. The designers that pick those finishes are not only disconnected from how the product will be used, they’re disconnected from at least some of the consumers!

[…] A Tale of Two Zippers (bunnie: studios) […]

[…] aesthetically unpleasing. Instead, people work eight hour shifts to assemble perfect zippers. [Bunnies Studios, via […]

[…] 7. The economics of zippers. […]

Nice insight article. The point about the manual component though; I wouldn’t feel sorry for the labourer so long as he has the choice to be there. If a machine took over the role, then he would have to find work elsewhere and perhaps there is no elsewhere for this person? It’s an age old argument, but worth highlighting.

[…] love learning stuff like this. The nuances and complexity of making even the simplest things can be amazing. This line in […]

Hi, I’m surprised that no one already pointed this out (I would, like you, have imagined within minutes), but your “vibrapot” is called a “deburring maching” among people in the know.

deburring machine, I meant.

How about having the tabs ride horizontally past two nylon-tipped probes that attempt to slide through the two holes. The one that wins will cause the other one to retract. Gravity then pulls down the other end, with the smaller hole, creating the desired alignment. As the dangling tab passes over the vertical feed rail, the winning probe is retracted.

Or feed the tabs into a rotating carousel with slots that will accept the full length of the tab in the desired orientation, but only to the depth of the large ring end if the tab goes in the other way, leaving the misaligned tabs sticking up. Then let the tabs ride in these slots past a cutout in the rail around the carousel that will allow the misaligned tabs to fall back into the bowl.

Or feed the tabs horizontally along a rail and use a microswitch or photocell to detect when the leading end of the tab is large instead of small, then activate a flipper to pop the tab back into the bowl.

Any of these solutions could be locally engineered and implemented within days.

. png

As someone who used to make those gloss finishes on plastic, yes, it was always demoralizing to see our products come back with fingerprints all over them. And then thermoformed into a beer cup.

Also, my experience with all these suggestions people are tossing off is that having management implement one of your suggestions is usually a humiliating experience as you see how much extra work it causes and how little it helps.

It’s the old “why can’t you just” uninformed outsider dilemma. I’m sure one of them will strike gold and become a rock star of factory automation

Why not just make the pullers symetrical? Do you really need a small end of the zipper? Then it would not matter which end of the puller is joined with the slider.

It’s been done, and produces an inferior product. This has all been thought out far more than any noob could imagine :D

Why not put the tab at the side with the smaller holes, let gravity drop them upside down then make the rail further down the line to flip them before assembly into the slider? This way the user doesn’t feel the bump. If not a tab, then two smaller dots/tabs near the smaller hole, which would have the same result without effecting the slider design.

Enjoyed the post. Makes you appreciate zippers more.

[…] http://www.bunniestudios.com/blog/?p=4364 […]

Satin finishes were actually quite a breakthrough! You see, they take work: you have to abrade the molds just right. But that’s something you do once per mold, not once per part.

I actually worked at a place where they transitioned from black satin to “piano black”, and it was heartbreaking.

On displays, it’s even dumber: satin finishes reduce glare. But no, everything has gone mirror-finish…

Not everything is mirror finish !

Yes, theese mirror screens are a pain in the ass.

But every business latop has a matte screen.

Just buy some used pro laptops, for example fujitsu lifebook, and you ge4t some nice matte screens, not that customer mirror crap.

A little top slide to reject the ones with the large hole first, run them through again. Double the speed somewhere else though to make up for less efficiency, or have them cascade to another conveyer for a second try.. maybe

Yeah, push it off onto another conveyer going in the opposite direction

> save another human the fate of having to manually align pullers into sliders for 8 hours a day

… by making the job go away altogether? I’m not sure he’d thank you for that.

That’s exactly what I was thinking. I’m sure if you asked the person with the zipper job he would not want his work to become automated.

[…] Design | A tale of two zippers […]

After watching a person join pullers to sliders for a couple minutes, I’m glad they have a job that feeds them and their families.

[…] A Tale of Two Zippers. (via) […]

Steve Jobs would surely disagree with you on the tabs and mirror-finish as well as many other designers who pride themselves with obsessive attention to detail / presentation =P =).

But I see what you’re saying! I guess people are a bit too far removed from how the goods they use are created. Cool article.

Seems to me what we really need is a designer who can style a zipper pull with the alignment bump in such a way as it feels natural. Kill two birds with one stone.

Thanks for visiting my factory. Excellent article, Bunnie!

I see many good suggestions in the comments. There are two reasons the puller in question could not be automated for assembly. The first reason is the lack of protruding tabs, as Bunnie pointed out. We actually got our customer (Nike) to accept tabs as a running change, provided it was done tastefully (similar to some of the suggestions above). The second, and main reason, is that the puller was not designed with manufacturability in mind – the puller is symmetrical, with the ONLY difference being a swoosh on one side and “nike” on the other. The customer also wants the puller to be assembled in a certain way (swoosh facing out when slider points up), which makes it difficult to align the puller through mechanical means only. We actually designed a one-sided tab, which would work, but the tab was unacceptably large.

Had we known that this would be a big volume item, we would have strongly suggested a change to the design to make our lives easier. However, this being the real world, you never know what will be a hit, and how long it will last. This particular puller is an extreme example, currently in its 5th year of production. The estimate of “millions” is pretty close – it’s only off by two. Two orders of magnitude, that is (yes, 10^8). As is the same every season, we do not know if the design will be changed out next season, at the slightest whim of the designer. Kind of like the unexpected hanging paradox.

The lead time, engineering effort and cost to efficiently automate the assembly process are significant enough to discourage development, as it is likely to not have a positive ROI. Also there are the real life issues of amortization, maintenance (cost, training, etc.), downtime, and how it will affect the worker’s wages. After all, when a human can assemble 3,000 pieces an hour @ about 0.07 cents per piece, sometimes the itch is better left unscratched.

Imagine a big plump fruit, just high enough that you cannot see how ripe it is with your current ladder. By the time you build a new ladder, the fruit might have already spoiled. As an engineer I would love to build the ladder, but as a businessman, it is not worth it. Yet.

With a cost of labor at $1.50 per hour and a worker cranking out 3000 connections per hour that works out to 1/20 of a cent. On a 7 cent zipper that has less than 1 cent of metal Daniel should have a nice return on 10^8 zippers. You might consider adding a little meat to the workers diet.

Some support for the female followers of this site! Some females just don’t get ample time to indulge themselves. I know, I know, careers, youngsters, partners all demand your time. Ladies isn’t it about time to really care for yourself frequently and treat yourself as that special person you happen to be. Self-pampering is dependent upon things like money and time. Many mothers are exceedingly distracted by the day-to-day associations to be bride, mothers and sometimes employee and mostly are aching for moments to just sit down and unwind. That’s more reasons why you’ll want a little “me” time. Especially if you’re busy taking care of lots of other people. and you simply imagine you don’t have any time, you make it for yourself! Read the entire article at the Url provided!

Wow that looks brilliantly automated factory! I am impressed! Anyway, I would not mind the tab if it means cheaper trousers. I think that labor work don’t cost too much anyway. The annual profits certainly outweigh the labor works entirely.

This is something made me think and appreciate those zippers more. Who knows that from a such small thing, it includes the use of automated machines which work great and involving so many processes to get high quality and detailed product.

[…] When product designers decide that they want a perfectly smooth ‘puller’ on their zips, thousands of Chinese people have to spend 8 hours a day manually aligning pullers with sliders. [Bunnie Huang] […]

Who knew zipper designers were such a persnickety group?

The problem is not the way the tabs are facing, it is that without the thickening they would jam going into the machine.

[…] 상품 디자이너가 원하는 완전히 부드럽게 잠기는 지퍼를 만들기 위해 수천명 중국인이 매일 8시간씩 지퍼 손잡이와 지퍼 위치를 맞춥니다. . [Bunnie Huang] […]