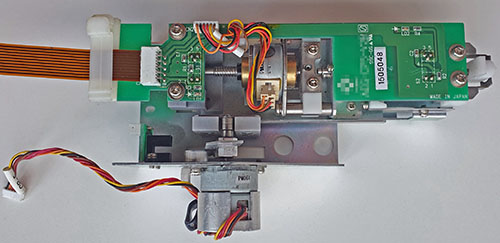

The Ware for January 2024 is shown below.

I picked up this little gizmo at a junk shop in Akihabara. I actually have no idea what the original purpose was, so I’m curious to see if anyone can convince me as to what this thing did, presumably for many years and millions of times. I got it mostly because it was a great price for a linear guide plus associated optical interrupters and motors (although I think the central motor’s bearing is busted, hence its junk shop fate). Fortunately the mounting patterns for these kinds of mechanical parts are almost, but not quite, standardized.

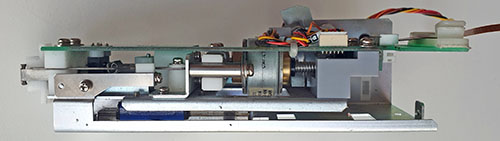

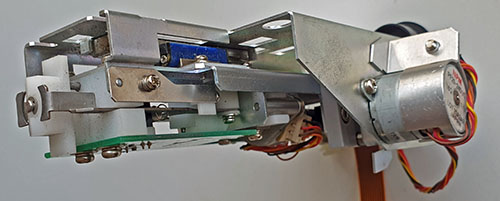

It appears to be a “grabby thing” of some sort. It looks like those “jaws” in the third photo spread out as they are extended and pull back in as they retract. One motor controls the sliding motion and the other the jaw gape width motion.

The jaws look as if they were designed to grab a grove in a shaft or something of similar topology. Neck/cap of a bottle in a vending machine?

The arrangement of the front end with the gripper jaws and the steel shaft poking out from the nylon wedge looks kinda like a lightweight version of automotive tools for pulling gears and bearings.

Looks like the ass-end actuator bits of a ticket dispenser like you see at a Japanese transit gate, but I’m totally spitballing. Omron and Nidec make a bunch of that stuff.

This almost looks like a mechanism from an Apple //GS floppy drive.

I looks like the shape of a Microsoft Kinect. Either that or some sort of OEM (AKA, here are the guts stick them in your own shell or integrate them into your own device.) barcode scanner.

It seem like a Barbarcut arcade machine but the schematic doesn’t add up.

It should be the smaller variance of the arcade machine where it extend the cutter and trying to cut the rope that hanging the prize.

Another possibility is the same mechanical design is use in Pachiko machine where they have fun physical moving object when you hit certain high score/combo

Doesn’t look like the total travel for either axis is all that large, so maybe X/Y stage for a microscope or other medical equipment for a sample?

Hi, Bunnie!

I’m legitimately not sure if this is the right place to ask, but I can’t find any other relevant website which is still active. Please do excuse me if you’re not interested/associated with this project any more!

Just to introduce myself real quick, I’m a 22 year old guy who is currently enlisted in the Republic Of Korea Air Force.

The ROKAF regularly holds startup competitions, a great opportunity for airmen to come together and develop their ideas (and possibly even end up making their ideas a reality)!

My team and I are developing an idea for a device that’ll help the elderly access information and health assistance.

We were trying to find ways to allow our device to be connected to a TV, via a “2 Devices -> 2 HDMI inputs -> (1 input uses chroma key, acting as overlay) -> combined input into TV” method.

I was initially unsuccessful in finding a solution to make this work, until I stumbled upon the NeTV (and subsequent NeTV 2).

Imagine my pleasure when I discovered such a perfect solution.. And my incredible sadness when I found out that it has been inactive for just about 10 years now.

I’m just leaving a comment to inquire if there is some sort of updated version of the NeTV which I’m unaware of and unable to find, or if you may be aware of some alternative solution for our method.

It would be amazing if this “use 2 inputs, 1 as chroma-keyed overlay” method could be used in our idea. So many new and fantastic opportunities to utilize it..

In any case, I would like to thank you for your impressive work, it speaks volumes how nobody has managed to replicate the technology since you first developed it (and produced a second iteration of it). I guess nobody realized the potential behind what it could bring for so many people.

Hoping this comment reaches you well,

Eojin Kim.

Hey — I responded to the email you had entered when creating your comment. Hopefully you didn’t put a fake email in there.

The two steppers appear to be wired unipolar. The one on the side is geared down and doesn’t seem to do much other than turn a small cam on a shaft through a slot/interrupter to sense position.

The other stepper is more instesting as it appears to have an internal ballscrew which it drives side to side. There’s a slot/interrupter on both ends of its axis of travel.

The side mounted geared stepper seems to be a latch to prevent the other stepper from moving. Since there’s already a motor on that axis, there must be a reason to lock that axis from externally induced movement. And it only locks in the one position, so it’s not a friction brake to lock some kind of movement stage. I would guess it’s to prevent some external manipulation of the positioner.

Given the pretty light construction of this device–milled plastic and stampted/bent metal–I wouldn’t not think it’s a lock. It’s most likely some kind of acceptor/dispensor typs of device on a publically facing machine.

Maybe it dispenses a product or takes in currenty. It seems to have a good amount of dust and junk built up on some of the parts, so that tells me it’s not embedded deeply in a device, but is near an opening–which agrees with the acceptor/dispensor theory.

The milled plastic and simple construction of the metal parts speaks low manufacturing volume and/or specific device customization of dimensions. Given the cost of such construction and the relative simplicity of the device, that makes me think it performs a task closely related to making money–bean counters don’t have trouble spending money on things they can see the direct impact of on profit/income.

If this were a higher volume of manufacture device used in more equipment either due to the populatiry of the mechanism or a standard function, I would expect to see molded plastic parts and cast metal parts. That tells me that whatever function this device performs, it’s not used in high volumes. To me,that rules out money handling. That’s a very standard and demanding job, so currency acceptors/dispensors are high volume and very purpose built.

That leaves some kind of product dispensor. It was mentioned earlier archie4oz mentioned transit ticket dispensor which seems possible, but I would expect those to be used in higher volumes than this mechanism appears to be made. I would tend to lean towards Jin’s idea of it being for some kind of recreational game. The thing that speaks against that is the locking mechanism. If this were a simple motion axis controller, it would have no need for such a strong locking mechanism.

Keith’s idea of a microscope movement stage is right out. The only thing to suggest it is the ballscrew, but that simply could be for long term reliability–not precise low-backlash motion control. The stepper in question doesn’t look to be precise enough for that task.

My summary is low volume, consumer facing, and deals with something of relatively high value. It was also meant to last a long time but not be expected to be abused.

I’m curious to find out what it is!

I think I may know the exact junk bin this comes from at 日米商事. More informally known as 秋葉原のスーパージャンク or just SuperJunk. My favorite junk shop in Akihabara. There’s a basket on the right side in front of the shop where over the last 10 years they’ve been slowly depositing various bits that seem to come from the same instrument/manufacturing line. For the most part these are fluidic processing parts (custom syringe pumps were common, they currently have a few heating elements which heat up a fluid as it passes through a line). One of these days I’m going to ask them if they know what kind of machine these came from.

I have a similar unit to this one here. I suspect in this case it’s designed to interface with a disposable syringe. The “grabby bit” clamps it in place and the whole thing sits on a slider. That’s my best guess anyway, here’s my unit with a syringe: https://ibb.co/d58wZSR

Hahah yep, it’s SuperJunk :) We might not know what machine it came from, but we know what store to get ’em from.

Huh, maybe it’s a packaging line then for chemicals into single-use syringes? Kind of like an epoxy of some sort?

Yep, could well be! There seems to be a never ending supply (or perhaps we are the only people buying them :)). So I’ll keep an eye out for anything that might provide a clue!