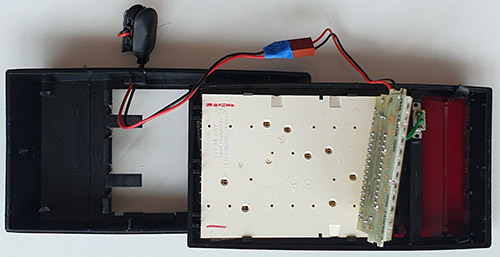

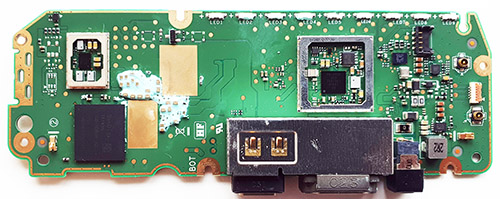

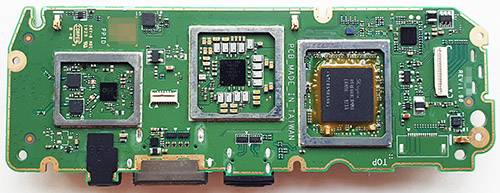

The Ware for May 2025 is shown below.

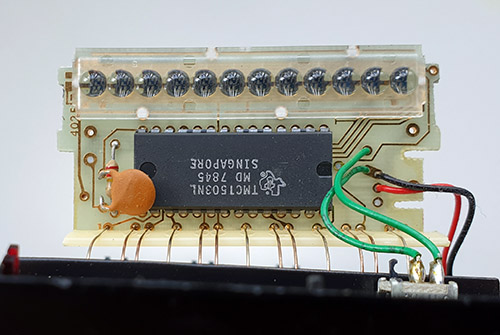

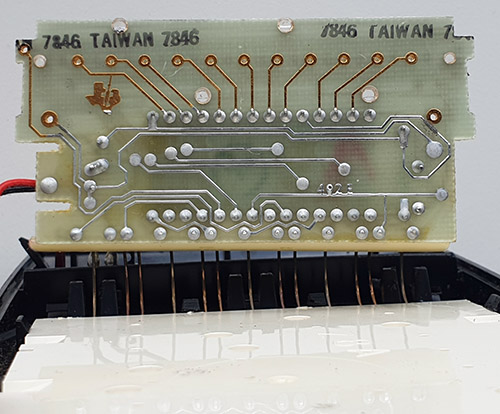

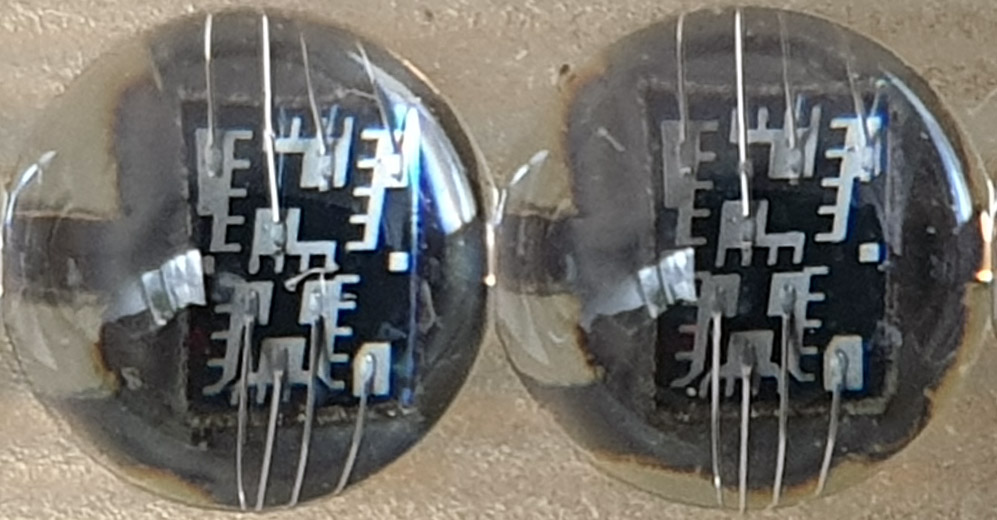

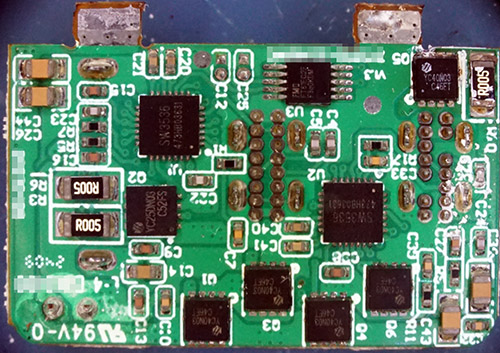

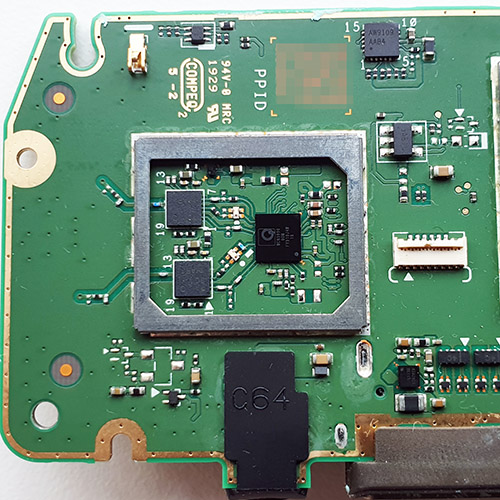

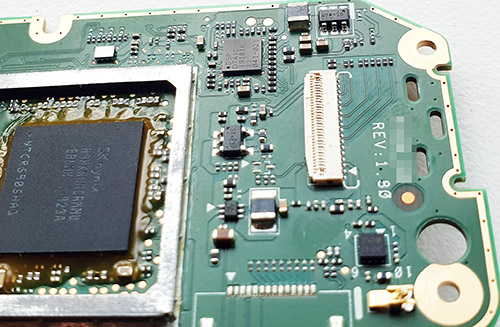

Because I really like to be able to read the part numbers on all the parts, here’s a couple more detail images of portions that didn’t photograph clearly in the above images.

This ware was donated to me by someone in person, but unfortunately the post-it note I had put on it to remind me who it was had long fallen off. My apologies; if you happen to see this, feel free to pop a note in the comments so you can be attributed for the contribution.

I made a point of not looking up the details of the ware before I did the teardown, so I could have a little fun figuring it out. While pulling it apart, the entire time I kept muttering to myself how this ware reeks of silicon valley startup with more money than sense. The hardware engineers who worked on this were clearly professional, well-trained, and clever; but also, whoever the product manager was had some Opinions about design, and incorporated lots of cost-intensive high-tech “flexes”, most of which I’m pretty sure went unappreciated and/or unnoticed by anyone other than someone like me taking the thing apart. For example, the board shown above is encased in a thixomolded two-part magnesium thermal frame with heat pipes, precision-machined thermal conduction blocks and gobs and gobs of thermal paste, which then necessitated a fairly tricky assembly procedure, and some brand-name custom-designed antennae to work around the Faraday cage caused by the metal casing. You’ll also note that despite the whole assembly being stuck in a metal case, each circuit subsystem still had an RF cage over it – so it’s metal cages inside a metal cage. This project must have had one heck of a tooling budget.

This was all for the sake of a “clean” design that lacked any visible screws. I’d say it also lacked visible cooling vents but ironically the final design had prominent ribbed structures, but they weren’t used for cooling – they were purely cosmetic and sealed over with an inner bezel. I feel like most of the cost for the thermal frame could have been avoided if they just let some air flow through the product, but someone, somewhere, in the decision chain had a very strong opinion about the need for a minimalist design that left little room for compromise. I would lay good money that the argument “but Apple does it this way” was used more than once to drive a design decision and/or shame an engineer into retracting a compromise proposal. Anyways, I found this product to be an entertaining case study in over-engineering.