I’ve gotten a few people asking me where I get my flex PCBs fabricated, so I figured I’d make a note here. I get my flex PCBs (and actually most of my PCBs, except laser-drilled microvia) done at a medium-sized shop in China called King Credie. Previously it was a bit hard to talk about them because they only took orders via e-mail and in Chinese, but they recently opened an English-friendly online website for quotation and order placement. There’s still a few wrinkles in the website, but for a company whose specialty is decidedly not “web services” and with English as a second language, it’s usable.

Knowing your PCB vendor is advantageous for a boutique hardware system integrators like me. It’s a bit like the whole farm-to-table movement — you get better results when you know where your materials are coming from. I’ve probably been working with King Credie for almost a decade now, and I try to visit their facility and have drinks with the owner on a regular basis. I really like their CEO, he’s been a circuit board fabrication nerd since college, and he’s living his dream of building his own factory and learning all he can about interesting and boutique PCB processes.

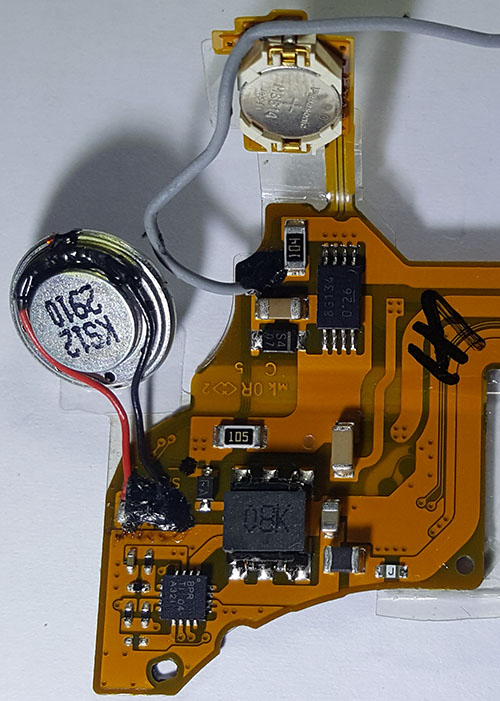

I like to say the shop is “just the right size” for someone like me — not so big I get lost in the system, not so small that it lacks capability. Their process offering is pretty diverse for a shop their size. In addition to flex PCB, they can do multi-layer flex, rigi-flex, metal cores (for applications that require built-in heatsinking like high power LEDs), RF laminates, and laminated EMI shielding films. They can also do a variety of post-processing, such as edge plating, depth-routing, press-fit holes, screen-printed carbon and custom soldermask and silkscreen colors.

If you’re new to flexible PCBs, check out their FPC stackup page for how to set up your design tool. Flexible and rigi-flex PCBs literally open a new dimension over traditional flat PCB designs — it’s a lot of fun to design in flex!

P.S. I was not paid to write this blog. It’s just that now that King Credie has an English website, I can finally answer the question of “where do you get your PCBs fabricated” with a better answer than “there’s this factory in China … but it’s all in Chinese, so never mind”.